News

MHI achieves 1,200-hr long-term durability test milestone on 90 MPa-Class ultra-high-pressure liquid hydrogen booster pump

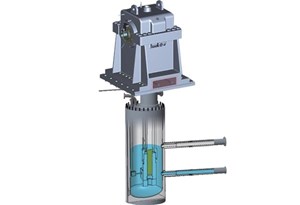

Mitsubishi Heavy Industries Ltd. (MHI) successfully achieved the key milestone of 1,200 hr of operation in a long-term durability test of its 90 MPa (900 bar) class ultra-high-pressure liquid H2 booster pump. Liquid H2 pumps are used at H2 refueling stations to refuel H2 fuel cell vehicles and H2 tube trailers.

During the test, the pump completed 1,500 refueling cycles without downtime or replacement of major parts used at the cryogenic temperatures. This validates MHI's best-in-class operational reliability in H2 refueling allowing for dependable high flowrates of 160 kg per hour at a discharge pressure of 90 MPa (900 bar). The results of this long-term durability test demonstrate significant progress on the path to a future H2 economy.

This test was conducted with FirstElement Fuel, Inc. (FEF), world-leader in H2 refueling solutions, at the Livermore H2 Hub under H2 refueling station conditions. The test started in April 2023 and was completed in November 2024. During this test, the pump:

- Completed 1,500 refueling cycles at cryogenic temperatures of approximately -253°C (-423°F)

- Achieved 1,200 hr of operations without downtime and without replacement of major parts

- Pumped approximately 140 tons of liquid H2 (the equivalent of refueling 5,000 fuel cell buses)

- Generated negligible boil-off gas during pump operation.

The test was an overwhelming success and proved that this pump will make positive contributions to the reliability and efficiency of H2 refueling stations.

The pump will be installed at a large-scale H2 station dedicated to clean commercial mobility in Japan and is scheduled to go into commercial operation in April 2025 simultaneously with the opening of the station.

MHI will continue to provide best-in-class solutions to reduce the carbon footprint around the world. Our ultra-high-pressure liquid H2 booster pump is currently being introduced to the global market. This and new advanced solutions will continue to add value on society's path to a future H2 economy.