News

Online Feature: Green H2: A critical balancing act─Part 1

Mika Kulju, President, Danfoss Drives

In the global discourse on climate change, hydrogen (H2) emerges as a highly contested energy carrier, igniting heated debates and capturing headlines worldwide. While some fervently tout it as a “miracle fuel”, others raise caution flags, branding it as a costly double-edged sword intertwined with the fossil-fuel industry.

Amid the urgency and complexity of finding sustainable solutions to combat climate change, it is easy to understand why advocates are looking for a silver bullet. Similarly, it is easy to understand why disputes around the efficacy of H2 are making it one of the most hotly debated topics of the green transition.

However, silver-bullet thinking and polarizing debates will not get us to net zero. Green H2 will play a critical role in the transition away from fossil fuels. H2 remains concentrated in traditional applications, and we need to see a rapid upscale in hard-to-abate sectors (e.g., heavy industry and long-distance transport). The good news is that we already have the necessary technologies to lower the cost of green H2 production.

To keep global average temperature increases under 1.5°C, we must replace fossil fuel technologies with ones powered by renewable electricity. After years of debate, stalling and inaction, this reality was finally recognized at COP28 in Dubai, UAE, where 198 Parties agreed to transition away from all fossil fuels to enable the world to reach net zero by 2050.1

Crucially, this historic transition away from fossil fuels means we must abandon legacy technologies and systems in favor of a fully electrified energy system. While the news from COP28 represents a welcome development, energy efficiency, electrification and renewables will only get us part of the way to net zero─albeit a large part. To plug the final piece in the energy transition jigsaw, we will rely on alternative low-emission fuels to decarbonize the most hard-to-abate sectors. Here, the key solution will be H2.

Low-emissions H2 is a versatile lever of decarbonization. It can be used as a means of storing excess renewable electricity in periods where supply outstrips demand. Similarly, when produced using renewable electricity, H2 can enable us to indirectly electrify sectors that otherwise may take decades to electrify (e.g., agriculture, aviation, shipping and heavy industry).

However, while the use cases of green H2 are vast, so is its demand for renewable energy. In fact, by 2050, H2 production will require more than half of today’s total electricity demand.2,3,4,5

As such, we must produce H2 efficiently and use it wisely if we are to maximize its benefits without breaking the bank or the energy grid. This includes repurposing existing gray H2 production facilities to green H2.

In this article, the author presents a balanced and systemic approach to H2. The author puts forward a set of principles that will enable politicians and other key decision makers to efficiently scale H2 production without putting an unmanageable strain on renewable energy production or financial resources. By reducing overall energy demand, producing H2 efficiently, and using it wisely, we can effectively decarbonize the sectors and processes that contribute an outsized proportion of global greenhouse gas (GHG) emissions.

H2 is no silver bullet, and as with all other climate technologies, we need a holistic and cost-efficient approach. However, there is no doubt that it will play a crucial part in the green transition. We already have the technologies available for a rapid, cost-efficient and sustainable build out of H2. All we need now is to stop dealing in absolutes and start embracing the opportunities ahead.

The terminology used when discussing H2 and H2 production in this article follows no international agreements or regulations. H2 produced via electrolysis might be perceived as “green” even if it does not consider the grid electricity’s origin. The terminology of H2 produced via electrolysis using renewable electricity varies, but in this issue, H2 produced via electrolysis using renewable electricity is referred to as green H2 and has a carbon intensity of close to zero. This issue will at times refer to low-emission H2, adopting the IEA and EU definitions of H2 produced via renewable electricity-based electrolysis and fossil fuels (natural gas and coal gasification) with carbon capture and storage (CCS).6,7,8 This term covers blue and green H2, which is widely used across the literature, but with no standard definition.

H2 explained. H2 is the most common chemical element in our universe. Despite being completely odorless, tasteless and colorless, it is a foundational component of nearly everything that sustains human life, including the water we drink, the sun that warms us and even our very anatomy itself. However, despite often being referred to as the essential building block of the universe, it is rarely found in its free (gaseous) state. But actually, in this state, it has the power to deeply decarbonize our energy system.9

Beyond its cosmic implications, H2 has some very real, very critical functions on Earth. For one, it is a very effective energy carrier, meaning it can serve as a means of storing energy. Similarly, H2 can be burned or converted into eFuels, which are synthetic fuels produced without fossil sources that can serve as a low-emissions alternative for traditional fossil fuels such as methanol or kerosene. If produced and consumed wisely, eFuels can have very little environmental impact, meaning their potential as a driver of the green transition is quite remarkable.10

Many sectors of our economy require highly energy-intensive processes. Think of cement and steel production, or long-haul aviation. Fully electrifying these sectors and powering them with renewable energy is still a way out, and with the urgency of the climate crisis, we must explore all possible opportunities. Indirect electrification through green H2 is a good catalyst to jump start the decarbonization journey while direct electrification technologies for heavy and high-temperature applications are being developed. H2 is a very viable alternative to the fossil fuels commonly used in these processes – an alternative that emits no GHGs when burned. As such, when used strategically and sparingly, it can be one of the key enablers of decarbonization in these sectors.11

If H2 is produced with renewable electricity (green H2) it can also serve as a key tool for stabilizing the future renewable electricity grid. Renewable energy production and demand come in waves, and oftentimes these waves do not align with one another. If the sun is shining or the wind is blowing but our lights and ovens are switched off, governments often pay energy suppliers to shut down production, which can cost exorbitant amounts of money. However, if we instead use this excess energy to produce H2, either for storage or direct use as a fuel, we can avoid curtailment costs and grid disruptions while stimulating a profitable and efficient H2 economy.12

As we have seen, H2 has many benefits. But it is a false hope to believe that H2 is a silver bullet to the climate crisis. As we will see in the following chapters, energy efficiency, direct electrification and a cost-efficient upscaling of green H2 will all be critical to meet global climate goals.

There are many ways to produce H2. However, there are no global agreements defining the different types of H2 produced, making it difficult to assign a specific level of emission to each means of production. The four most prevalent types of H2 production are described below. Other forms of H2 production such as white, turquoise or purple are less common or are still in the early stages of development and are therefore omitted from the discussion.

- Green H2: Produced through a process called water electrolysis, where electricity splits water into H2 and oxygen. In order for H2 to be called green, the power supply must stem from renewable sources.13 Green H2 can have a carbon footprint from 0.5 kg−6 kg of CO2e/kg of H2 and is one of the most promising options to supply low-emission H2 in the future.14,15

- Gray H2: Produced with fossil fuels such as natural gas or coal. Usually, gray H2 is produced through processes called steam methane reforming (SMR) or coal gasification. Producing gray H2 emits vast amounts of CO2, and accounts for 95% of the global H2 production today. Emitting 10 kg−26 kg of CO2e/kg of H2, this is not a suitable option for the green transition.16,17

- Blue H2: Produced in the same way as gray H2 but the carbon emissions are captured and stored. At best, 85%−95% of the carbon can be captured, which means that 5%−15% is still emitted.18 Blue H2 is considered a low- emission H2 but emitting 1.5 kg−3 kg of CO2e/kg of H2, it is not the cleanest option.19

- Pink H2: Produced via water electrolysis like green H2, but with electricity from nuclear power plants. Emissions from pink H2 can be as little as 0.1 kg−3 kg CO2e/kg of H2.20 However, nuclear power is a heavily debated issue and brings with it a host of political considerations.

Water electrolysis: The pathway to green H2. Conventional methods for producing H2, almost all of which use fossil fuels, leave massive footprints. Today, these account for nearly all global H2 production. However, there are other ways to produce H2 that will only leave a small footprint, but which right now accounts for only 0.1% of global production.21 The most viable low- emissions process is called water electrolysis.

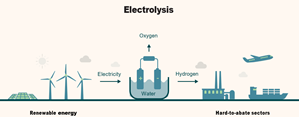

Water electrolysis is a process where electricity is used to split water (H2O) into its base molecules, H2 and oxygen (O2). While oxygen can be released into the air or captured to reuse for other purposes, the H2 can be stored and used for many functions, such as in industrial processes or the production of fertilizer, fuels, thermal energy and electricity. In cases where the H2 is produced via electrolysis run by renewable electricity (i.e., green H2), the end-use product can be used to decarbonize processes where H2 can be implemented as an alternative fuel.

H2 is a key element in many countries’ climate strategies. To realize the goals set by the Paris Agreement, electrolysis capacity must reach more than 550 gigawatts (GW) by 2030. However, planned projects will bring the capacity to 170 GW−365 GW in 2030.22 This means we must either radically ramp up H2 production, or look at energy efficiency measures to lower the demand. Given the sheer cost and resource intensity of H2 production, the most cost-efficient strategy is to first implement all possible electrification and energy efficiency measures, then meet the remaining (lower) demand with H2.

While electrolysis is quite expensive, the International Renewable Energy Agency suggests that reducing the cost of electrolyzers can reduce the long-term investment costs by up to 80%.23 As such, making early investments in efficient electrolysis can help to lower the lifetime cost. In the next chapter, we will explore how we already have the necessary technology available to lower the cost of green H2 production (FIG. 1).

The International Energy Agency (IEA) estimates that the global electricity demand for electrolysis in a net-zero scenario will be 14,800 TWhr by 2050.24 This will be largely driven by ambitious strategies from some of the world’s largest energy consumers, such as the U.S., China and the EU.25,26,27 So, even if we successfully reduce the overall demand for H2 by maximizing the energy efficiency of all elements across our energy system, we will still need incredible amounts of electricity to produce enough H2 to meet our net zero goals.

Which steps can we take to produce H2 in a way that does not cripple our energy system through excessive demand on renewable energy production? First and foremost, we must consider if there are other, cheaper alternatives than H2, such as direct electrification or lowering overall energy demand. Then we must maximize the energy efficiency of the electrolysis process. This means minimizing the input of renewable electricity and water for electrolysis, both of which are critical, and in many places, scarce resources for use beyond H2 production.

Energy conversion is both very simple and astonishingly complex. Put simply, it means changing one form of energy to another. For example, this could be wind to electricity, electricity to H2 or natural gas to heat. However, in practice, successfully converting energy requires incredible feats of engineering. Mastering the science and implementation of energy conversion will be fundamental if we are to decarbonize our energy system.

Every time energy is converted from one form into another, some of it is lost in the process. Most often, this energy loss comes in the form of heat. This heat loss can often be attributed to inefficient conversion machinery. For example, to propel a car down the street, one form of energy (e.g., electricity or gasoline) must be converted into another (e.g., movement). However, partly because gasoline engines create more excess heat, they have a lower energy efficiency. In fact, gasoline engines lose on average 64%−75% of energy, compared to only 15%−20% for electric vehicles.28

In this case, the electric vehicle is converting energy more efficiently, thereby using less to achieve the same result. These basic rules of thermodynamics also apply to H2 production. Indeed, there are more and less efficient ways of producing it, and minimizing energy loss by maximizing conversion efficiency will be critical as we continue to rapidly scale H2 production globally. Conversion of electricity to H2 creates an energy loss of roughly 30%.29 But there are critical steps we can take with technology that already exists today to minimize this energy loss. There is an entire ecosystem of technologies around producing H2, for instance for cooling and pumping. Prioritizing energy efficiency during all steps can have a great impact and make the green transition quicker and cheaper.

The efficiency of electrolyzers is essential in lowering production costs and optimizing the output. A new type of electrolyzer design can significantly increase efficiency through internalizing cooling, a design inspired by the proven and widely applied heat exchanger technology. For H2 to be used, it must be pressurized. This is another production process which requires large amounts of energy. Implementing pressurization into the electrolysis process, instead of having it as an extra step after it leaves the electrolyzer, is an essential measure to implement efficient green H2 production. By using efficient high-pressure pumps to pressurize the core of the electrolyzer (or the stack), where the water is split, the pressurization can significantly increase the efficiency of electrolysis.

Water usage in production. Producing H2 requires significant amounts of water. In areas that face challenges with water scarcity, H2 can add additional stress to the system if not planned properly.30

Gray H2 production requires water for processes such as steam generation and cooling, and blue H2 production needs additional cooling water for CCS. Green H2 production splits water into H2 and oxygen, while the cooling demand is also substantial. While all H2 production requires some amount of water, green H2 consumes less water than blue H2, and oftentimes less than gray H2. Actually, blue H2 consumes 24 liters (l)−49 l of water per kg of H2, compared to 18 l−31 l for gray H2 and 18 l−22 l for green H2.31

Although electrolytic H2 production will require less water than other forms of H2 production, local water scarcity is a real issue. This is especially relevant in regions hit by recurring droughts and with limited access to fresh water. As cooling of the electrolyzer can have a significant pull on local water resources, the planning of H2 production must always consider local needs and resource availability. However, certain cooling technologies, such as dry cooling, can serve as another method of driving down water consumption in H2 production.

Careful planning of green H2 production and use of state-of-the-art technology can address the concerns and reduce the impact of green H2’s water footprint. For example, production can be coupled with desalination and wastewater facilities and provide water for domestic use. Desalination of water requires energy, and with the vast amounts of electrolytic H2 in the future, the energy demand for desalination is not a trivial concern. There are many ways to purify water, but using highly efficient high-pressure pumps will save huge amounts of energy. Minimizing the cost, energy loss and energy demand of green H2 production means we must look for ways to maximize efficiency of each of the links in the H2 chain. H2T

LITERATURE CITED

1 COP28 (2023). COP28 delivers historic consensus in Dubai to accelerate climate action.

2 IEA (2022). World Energy Outlook, p. 136.

3 IRENA (n.d.). Policies for green hydrogen.

4 BloombergNEF (2022). New Energy Outlook.

5 Deloitte (2023). Green hydrogen: Energizing the path to net zero, p. 13.

6 IEA (2022). World Energy Outlook, p. 327.

7 IEA (2023). Towards hydrogen definitions based on their emissions intensity.

8 European Commission (2020). COMMUNICATION FROM THE COMMISSION TO THE EUROPEAN PARLIAMENT, THE COUNCIL, THE EUROPEAN ECONOMIC AND SOCIAL COMMITTEE AND THE COMMITTEE OF THE REGIONS: A hydrogen strategy for a climate-neutral Europe, p. 3-4.

9 IEA (2022). World Energy Outlook, p. 136.

10 IRENA (n.d.). Policies for green hydrogen.

11 BloombergNEF (2022). New Energy Outlook.

12 Deloitte (2023). Green hydrogen: Energizing the path to net zero, p. 13.

13 IRENA (2020). Green Hydrogen: A guide to policy making, p. 8-9.

14 IEA (2023). Global Hydrogen Review, p. 87-88.

15 Copenhagen Climate Centre. Identifying the differences in between green, low-carbon, and renewable hydrogen. p. 10. UN Environment Programme

16 IEA (2023). Global Hydrogen Review, p. 87-88.

17 IRENA (2020). Green Hydrogen: A guide to policy making, p. 8-9.

18 IRENA (2020). Green Hydrogen: A guide to policy making, p. 8-9.

19 IEA (2023). Global Hydrogen Review, p. 87-88.

20 IEA (2023). Global Hydrogen Review, p. 87-88.

21 IEA (2023). Global Hydrogen Review, p. 68.

22 IEA (2023). Electrolysers, Tracking Electrolysers.

23 IRENA (2023). Green Hydrogen for Sustainable Industrial Development, p. 19.

24 IEA (2022). World Energy Outlook, p. 136.

25 The White House (2023). Biden-Harris Administration Announces Regional Clean Hydrogen Hubs to Drive Clean Manufacturing and Jobs.

26 IEA (2022). Opportunities for Hydrogen Production with CCUS in China – Executive summary.

27 EU (2022). Energy – Hydrogen.

28 U.S. Department of Energy (n.d.). Where the Energy Goes: Electric Cars.

29 Buitendach et al. (2021). Effect of a ripple current on the efficiency of a PEM electrolyser. Results in Engineering, vol. 10, p. 1-13.

30 Tonelli et al. (2023). Global land and water limits to electrolytic hydrogen production using wind and solar resources. Nature Communications 14, art. no. 5532.

31 IRENA (2023). Water for hydrogen production.