News

Online Feature: Transforming the future: Yokogawa's YNOW2024 highlights innovation in energy transition and industrial automation

Story By: Tyler Campbell, Managing Editor

Yokogawa’s YNOW2024: Impact Your World event served as a pivotal gathering for industry leaders, innovators and professionals, highlighting the transformative power of industrial automation and digital technologies. Showcasing best practices, methodologies and the latest advancements from end users, Yokogawa, KBC (a Yokogawa company), and their partners, the event emphasized how collaboration and cutting-edge solutions can drive positive change across operations, business and society.

With a focus on sustainability and corporate responsibility, YNOW2024 explored critical themes such as industrial autonomy, energy transition and lifecycle management, offering valuable insights for those shaping the future of business and technology. H2Tech (H2T) interviewed Koji Nakaoka (KN) at the event to discuss Yokogawa’s approach to innovation and the energy transition.

Nakaoka is the Senior Vice President & Executive Officer for Yokogawa’s Energy & Sustainability Business Headquarters. He has been working in global sales for more than 30 yr and has a broad range of experience in the marine upstream and downstream sectors. Currently, Nakaoka is focused on energy transition trends and the transformation of Yokogawa’s energy business using digital transformation solutions, and the optimization of renewable energy and other operations for the company’s client base.

(H2T): What are the similarities between the liquified natural gas (LNG) liquefaction, transportation and vaporization processes—an area where Yokogawa has vast experience—and the hydrogen (H2) industry?

(KN): Yokogawa has been involved in the LNG industry for more than 50 yr. In the LNG value chain, our company has contributed to society in the fields of control, measurement and information in various areas such as natural gas extraction, liquefaction, transportation, regasification, power generation and city gas production. This is because we understand our customers’ processes and operations, allowing us to provide systems and applications that meet the high reliability required. The LNG business involves a cross-national supply chain, with different stakeholders and players in production, transportation and usage. Yokogawa is also trusted by customers for its global structure in sales, engineering and maintenance support. I think this will be relevant in the H2 business.

(H2T): How is Yokogawa approaching the H2 industry from an organizational point of view?

(KN): The H2 business seems to have different maturity levels depending on region and customer. Yokogawa has a global matrix structure for each business and works closely with customers in each region. Also, since Europe is ahead of the curve in H2, we have set up a center of excellence in Europe. We are currently participating in external collaborations and industry-academia joint research for H2 and ammonia.

(H2T): What are some of the major H2 projects that Yokogawa is involved in?

(KN): Yokogawa has been appointed as the main automation contractor (MAC) by Shell for the construction of the Holland Hydrogen I plant in Rotterdam, set to become one of Europe’s largest renewable H2 facilities. It is scheduled to begin operations in 2025 and use a 200-megawatt (MW) electrolyzer powered by offshore wind energy to produce up to 60,000 kg/d of green H2 and replace the gray H2 at the refinery.

Yokogawa will optimize plant operations through its system integration expertise, aligning with its system of systems (SoS) concept. SoS refers to a collection of independently operated and managed systems connected to form a larger system that delivers synergies and value to all stakeholders in a plant, enterprise, supply chain or society ecosystem. We aim to support decarbonization strategies and foster a sustainable society through collaborative projects, like this one, across the H2 supply chain.

Yokogawa is also providing an energy management system (EMS) for the initial phase of the Yuri Green Hydrogen Project. The Yuri project is being undertaken in the Pilbara region of Western Australia by Yuri Operations Pty Ltd, a joint venture between ENGIE Renewables Australia Pty Ltd. and Mitsui & Co., Ltd. A consortium consisting of the engineering, procurement, construction and commissioning (EPCC) companies Technip Energies and Monford Group Pty Ltd. is constructing these facilities, which will consist of an 18-MW solar power plant, an 8-MW battery energy storage system (BESS), and a 10-MW electrolyzer.

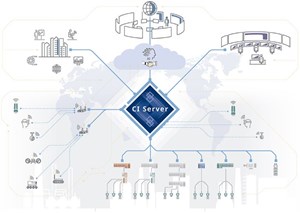

In addition, Yokogawa will be providing the integrated control system (ICS) for Phase 0 of the project. Yokogawa’s ICS is built around its Collaborative Information Server (CI Server) that facilitates centralized data management and rapid decision-making by integrating diverse equipment data from the H2 facility and the adjacent ammonia plant.

(H2T): You are utilizing CI Server for both the Holland Hydrogen I plant and Yuri Green Hydrogen Project, and Yokogawa claims that it aims to provide value as a trusted partner in the SoS domain. Could you tell us how you are providing value to the market with this product?

(KN): CI Server is part of our OpreX Control and Safety System family. The server supports remote operations from any location via web browsers, reducing required onsite presence and fostering collaboration among operators, maintenance experts and decision-makers. The CI Server automates tasks like equipment monitoring, inventory management and energy consumption analysis.

An example of the value it provides is what was evaluated for Shell’s Holland Hydrogen I project, which was the capability supplied by our company to integrate and operate different vendors' subsystems, such as production, pipeline transportation, storage and supply. Moving forward, all data will be connected and integrated, and it will be necessary to firmly understand the meaning of that data and explore customer issues.

In a recent press release, we announced that we have received an order to supply an integrated automation and energy control and monitoring system for an offshore green H2 production and storage pilot plant in Europe, owned by the Crosswind joint venture between Shell and Eneco. Our CI Server will play an important role in this complex system, which also utilizes a renewable EMS from BaxEnergy, which recently joined the Yokogawa Group.

The strength of our CI Server is its ability to integrate other companies' products as well as ours. The world has entered an age in which things are interconnected in ever greater and more complex ways to solve issues, helping create a sustainable society. Yokogawa aims, through industrial automation to industrial autonomy (IA2IA) and smart manufacturing, to provide value based on its SoS concept.

(H2T): Ammonia is attracting attention as a carrier of H2. How can Yokogawa support the ammonia supply chain?

(KN): Currently, there is an increasing number of passenger ships, car carriers and other ships known as LNG-fueled ships that run on LNG instead of oil as fuel for environmental reasons. Yokogawa provides the control system for the fuel gas supply system (FGSS) for these LNG-fueled ships and is utilizing the experience it has gained from ships using other types of fuel. Our experience has been recognized in the field of new alternative energies such as H2 and ammonia, and it was applied in the FGSS for a ship transporting ammonia. Similarly, we are also participating in the study of transporting liquefied H2.

(H2T): Yokogawa’s involvement in sustainable projects involving H2 and ammonia displays the company’s ambitions to contribute to the energy transition. Events like YNOW2024 show how automation is transforming the industrial landscape by integrating advanced technologies and systems for enhanced efficiency and connectivity.

For more information, visit: https://h2-tech.com/news/2024/11-2024/yokogawa-to-provide-integrated-automation-and-monitoring-system-for-pioneering-green-h-sub-2-sub-platform/