News

Kawasaki starts construction of a demonstration facility for centrifugal H2 compressor for H2 liquefaction plants

Kawasaki Heavy Industries, Ltd. has begun construction of a demonstration facility for the KM Comp-H₂, a centrifugal H2 compressor for H2 liquefaction plants under development, at Harima Works of the company (Harima-cho, Kako-gun, Hyogo Prefecture).

The development and demonstration of this machine are being carried out as part of a Green Innovation Fund project: Development of large-scale high-efficiency machineries for H2 liquefiers sponsored by the New Energy and Industrial Technology Development Organization (NEDO). The manufacturing of the demonstration machine has now been completed, and construction of the demonstration facility has begun. Notably, this is the world's first centrifugal H2 compressor for use in H2 liquefaction plants.

Construction of the demonstration facility will continue forward toward completion in November 2025, followed by one year of operational testing.

This machine is responsible for the process of boosting the pressure of refrigerant H2 gas, which is used to cool the feed H2 gas that serves as the raw material for liquefied H2. Improving the efficiency of the liquefaction process is essential for reducing H2 supply costs. Kawasaki, drawing on over half a century of experience and expertise in compressors for the energy and resources sector, is developing a large-scale centrifugal H2 compressor designed for 100% pure H2 to enhance liquefaction efficiency.

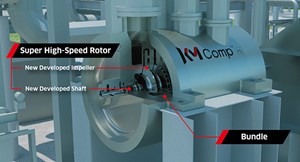

This machine achieves "high efficiency, high pressure boost with a compact footprint" compared to conventional H2 compressors by incorporating technological innovations such as the development of new impellers, the machine’s key component, and the adoption of a centrifugal design capable of handling large flowrates.

The knowledge and data gained through the development of this machine will also be applied to the development of centrifugal H2 compressors for H2 supply pipelines, where are expected to see higher demand in line with the expansion of H2 energy.

- Achieving a boosting performance that significantly surpasses existing H2 compressors: Ultra-high-speed rotating technology using the newly developed impeller makes it possible to efficiently boost H2, a small molecular weight gas.

- By adopting centrifugal type design that enables handling high flowrates, the required installation area is reduced to one-seventh compared to existing H2

Kawasaki is promoting the development of the H2 supply chain with a focus on the future expansion of H2 energy use. In order to achieve global carbon neutrality, the company will continue to actively work on the development of technology related to the production/transportation/storage/utilization of H2.