News

Utility achieves H2 production using steel manufacturing off-gases

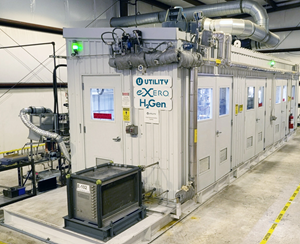

Utility announced the successful operation of the company’s H2Gen system at a major steel plant in North America. Utility’s H2Gen system successfully produced the world’s first H2 using steel plant off-gas (blast furnace gas) in an elegant single process step under actual site conditions. Additionally, this marks the industry’s first successful implementation of a system that can produce clean H2 from water without the need for electricity.

The H2Gen system is now proven as the leading economic clean H2 platform solving the steel industry’s significant clean energy challenges. It is a solution that is commercially available, cost-effective, offers a profitable pathway to a clean energy transition and easily integrates with existing assets.

Steel production is vital to industrial progress, but it is also one of the world’s most energy-intensive processes, facing significant energy transition hurdles in reducing its carbon footprint. These challenges include:

- Capital costs in the billions of dollars for alternative steelmaking technologies compared to the blast furnaces used in making most of the steel globally

- Limited space and infrastructure constraints for making economic onsite clean H2 that can reduce carbon footprint of existing steel plants

- The need to balance sustainability with productivity and global competitiveness while lacking economic carbon capture solutions for the steel industry.

Utility’s H2Gen system offers a groundbreaking solution to these challenges by producing H2 from water using industrial off-gases, such as blast furnace gas. The H2Gen system enables onsite H2 production with a compact footprint while delivering enriched CO₂ at a single point for cost-effective carbon capture. With more than 3,000 hr of successful operation at a major steel plant, H2Gen has demonstrated its ability to drive a cost-effective, scalable, reliable and commercially ready energy transition pathway for heavy industries including steel, biogas-to-H2, chemicals, refining, upstream oil & gas, power, and H2-powered data centers.

REAL-WORLD PROJECT RESULTS:

- H2 Production: The H2Gen system consistently produced H2 onsite without the need for electrical input to the reaction.

- Seamless Integration: Designed for compatibility and operational simplicity, the modular, factory-built H2Gen system integrates with existing steel plant processes with minimal pre- and post-gas treatment, enhancing operational efficiency.

- Robust Performance: The system demonstrated significant flexibility, handling a wide variety of feed gas conditions and could restart in less than 15 minutes after feed gas outage events.

- Cost-Effective and Scalable Solution: By minimizing operating and capital costs with a very small onsite footprint and modular scalability, H2Gen provides a practical, economic pathway to clean H2 production for decarbonizing steel manufacturing, among many other hard-to-abate industry sectors.

"Decarbonizing heavy industries like steel, mobility, chemicals, refining, and power has been one of the toughest challenges in the energy transition — until now. Our successful deployment of H2Gen at a major steel plant proves we can deliver scalable, economic, clean H2 solutions that seamlessly integrate with existing infrastructure and assets. H2Gen is the only commercially viable solution for producing clean H2 in hard-to-abate industries like steelmaking,” stated Parker Meeks, chief executive officer of Utility.

“Utility is rapidly scaling to meet global demand, with strong momentum in steel, biogas-to-H2 for mobility and beyond. Our H2Gen systems provide an economic, modular solution without the high costs and infrastructure barriers of alternative H2 technologies. With strong customer and partner momentum including the recent ArcelorMittal funding and GH EnA Project Development announcements, we are accelerating the shift to clean H2 at scale."