News

Hanyang University researchers discovered new breakthrough catalyst for cheaper green H2 production

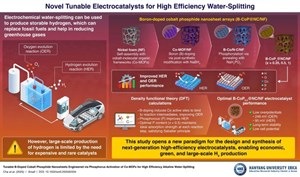

H2 is a clean energy source that can help reduce greenhouse gas emissions. However, its large-scale production is currently impeded by the need for expensive and rare catalysts, required for electrochemical water-splitting. In a new study, researchers have developed novel tunable boron-doped cobalt phosphide nanosheet-based electrocatalysts using metal-organic frameworks. These electrocatalysts offer high efficiency, low cost, and long-term stability, with the potential to enable large-scale H2 production.

To reduce greenhouse gas emissions and combat climate change, the world urgently needs clean and renewable energy sources. H2 is one such clean energy source that has zero carbon content and stores much more energy by weight than gasoline. One promising method to produce H2 is electrochemical water-splitting, a process that uses electricity to break down water into H2 and oxygen.

Unfortunately, large-scale production of H2 using this method is currently unfeasible due to the need for catalysts made from expensive rare earth metals. Among these, transition metal phosphides (TMPs) have attracted considerable attention as catalysts for the H2 generating side of the process, known as H2 evolution reaction (HER), due to their favorable properties. However, they perform poorly in the oxygen evolution reaction (OER), which reduces overall efficiency.

In a recent breakthrough, a research team led by Professor Seunghyun Lee, including Mr. Dun Chan Cha, from the Hanyang University ERICA campus in South Korea, has developed a new type of tunable electrocatalyst using B-doped cobalt phosphide (CoP) nanosheets. Prof. Lee explains, "We have successfully developed cobalt phosphides-based nanomaterials by adjusting boron doping and phosphorus content using metal-organic frameworks. These materials have better performance and lower cost than conventional electrocatalysts, making them suitable for large-scale H2 production." Their study was published in the journal Small on March 19, 2025.

The researchers used an innovative strategy to create these materials, using cobalt (Co) based metal-organic frameworks (MOFs). "MOFs are excellent precursors for designing and synthesizing nanomaterials with the required composition and structures," noted Mr. Cha. First, they grew Co-MOFs on nickel foam (NF). They then subjected this material to a post-synthesis modification (PSM) reaction with sodium borohydride (NaBH4), resulting in the integration of B. This was followed up by a phosphorization process using different amounts of sodium hypophosphite (NaH2PO2), resulting in the formation of three different samples of B-doped cobalt phosphide nanosheets (B-CoP@NC/NF).

Experiments revealed that all three samples had a large surface area and a mesoporous structure, key features that improve electrocatalytic activity. As a result, all three samples exhibited excellent OER and HER performance. An alkaline electrolyzer developed using the B-CoP0.5@NC/NF electrodes showed a cell potential of just 1.59 V at a current density of 10 mA cm-2, lower than many recent electrolyzers. Additionally, at high current densities above 50 mA cm-2, it even outperformed the state-of-the-art RuO₂/NF(+) and 20% Pt-C/NF(−) electrolyzer, while also demonstrating long-term stability, maintaining its performance for over 100 hours. Density functional theory (DFT) calculations supported these findings and clarified the role of B-doping and adjusting P content.

"Our findings offer a blueprint for designing and synthesizing next-generation high-efficiency catalysts that can drastically reduce H2 production costs," said Prof. Lee. "This is an important step towards making large-scale green H2 production a reality, which will ultimately help in reducing global carbon emissions and mitigating climate change."