News

Hydrogen: A driving force behind the decarbonization of TotalEnergies' refineries in Europe

Decarbonizing TotalEnergies’ operated sites (Scope 1 and 2) is at the heart of their ambition to supply more energy while reducing greenhouse gas (GHG) emissions. TotalEnergies is committed to reducing the carbon footprint associated with the production, transformation and supply of energy to its customers. One of the levers identified by the company is the use of low-carbon H2 to decarbonize its European refineries, which would reduce their direct CO2 emissions by up to 3 MMtpy by 2030.

The differences between green, gray and blue H2. H2 is an energy carrier that can be produced using various processes:

- Green H2 (also known as renewable H2) is produced by water electrolysis, a process that separates water (H2O) into oxygen (O) and H2 by means of an electric current. H2 is called green if the electricity used for the process is of renewable origin (wind or solar).

- Blue H2 (also known as low-carbon H2) is produced from the transformation of fossil fuels, but the CO2 emitted during its production is captured for reuse or storage, using CO2 capture and sequestration (CCS) processes. Low-carbon H2 also refers to H2 produced by electrolysis, using electricity from low-carbon energy sources, notably nuclear (commonly referred to as yellow H2), with a significant reduction in GHG emissions over the entire lifecycle, compared with H2 produced using existing techniques.

- Gray H2 is produced from fossil fuels (natural gas) using a steam-reforming process that separates the H2 atoms from the carbon atoms. This technique emits high levels of CO2. Gray H2 is widely used in refineries, mainly to desulfurize fuels.

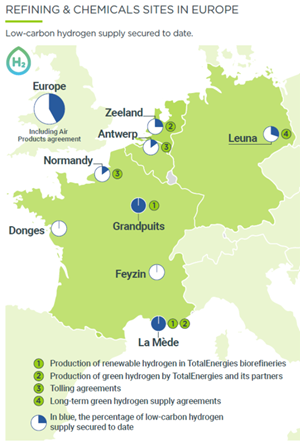

A massive call for tenders to decarbonize TotalEnergies’ refineries in Europe. In September 2023, TotalEnergies launched a call for a tender to use up to 500 kt/yr of H2 consumed in its European refineries starting in 2030. Four types of projects are being launched to help develop a European low-carbon H2 market:

- Biohydrogen production units using biomass gas are produced in TotalEnergies’ biorefineries. This biohydrogen will be used in particular to produce sustainable aviation fuels (SAFs)

- Electrolyzer projects powered by TotalEnergies renewable electrons, through:

- Joint venture projects between TotalEnergies or a partner

- Contracts for electrons supplied by TotalEnergies

- Long-term third-party purchases of green H2.

Biohydrogen production units in TotalEnergies’ biorefineries. In 2024, TotalEnergies’ announced a project for a renewable H2 production unit to be built and operated by Air Liquide on TotalEnergies’ La Mède platform. With a capacity of 25,000 tpy of H2, this unit will recycle co-products from the TotalEnergies biorefinery. The H2 will then be used by the biorefinery to produce biodiesel and SAF. Adaptation of the platform will reduce the biorefinery's GHG emissions by 130,000 tpy from 2028 onwards.

On TotalEnergies’ Grandpuits platform, Air Liquide is building a unit to produce around 20,000 tpy of renewable H2, thanks to the recycling of residual biogas from the biorefinery. In addition, this unit will be equipped from the outset with Air Liquide's Cryocap CO2 capture technology, enabling it to contribute to reducing the platform's carbon footprint by capturing over 110,000 tpy of CO2 and reusing it in agri-food and industrial applications.

The renewable, low-carbon H2 thus produced will be used primarily by the biorefinery for the production of sustainable jet fuel. This investment will avoid the emission of 150,000 tpy of CO2e, compared with existing processes.

ELECTROLYZER PROJECTS TO PRODUCE GREEN H2 WITH TOTALENERGIES’ PARTNERS

OranjeWind: A wind farm to supply green H2. To leverage its position as an integrated electricity player, in 2024 TotalEnergies acquired a 50% stake in the OranjeWind offshore wind farm in the Netherlands, with a total capacity of 795 MW, from the German developer RWE. TotalEnergies will dedicate its share of the renewable electricity production from this project to power 350-MW electrolyzer projects. These will produce about 40,000 tpy of green H2 for the decarbonization of TotalEnergies’ refineries in Northern Europe.

In the Netherlands, TotalEnergies and Air Liquide have set up a 50/50 joint venture to build and operate a 250-MW electrolyzer at the Zeeland refinery. The project, that will be fueled by OranjeWind, will produce up to 30,000 tpy of green H2, will be commissioned in 2029 and will reduce CO2 emissions from the Zeeland site by up to 300,000 tpy of CO2e.

Supplying renewable electricity for green H2 production. TotalEnergies has signed long-term tolling agreements with Air Liquide to supply renewable electricity to dedicated electrolysis capacity operated by partners, who in turn supply them with green H2. The aim is to decarbonize the Normandy and Antwerp sites.

As part of Air Liquide's 200-MW electrolyzer project, TotalEnergies has signed a tolling agreement to dedicate 130 MW of this electrolyzer to the production of 15,000 tpy of green H2 for the Antwerp platform. Upstream of the electrolyzer, TotalEnergies will supply renewable electrons produced by the OranjeWind wind farm to Air Liquide for use in the production of green H2. The project is scheduled to be operational by the end of 2027 and will reduce GHG emissions at the Antwerp site by up to 150,000 tpy.

In 2023, TotalEnergies and Air Liquide have signed an agreement for the long-term supply of green, low-carbon H2 to the Gonfreville platform in Normandy. The project will supply 10,000 tpy of green H2 to the TotalEnergies platform in Normandy, and up to 5,000 tons of low-carbon H2 from the second half of 2026. It comprises two integrated components:

- The production of green, low-carbon H2 by the Normandy electrolyzer, built and operated by Air Liquide, with a total electrical capacity of 200 MW. TotalEnergies will have access to half of this production capacity, corresponding to the quantity of H2 delivered to its refinery.

- The supply by TotalEnergies of around 700 GWh per year of renewable, low-carbon electricity to power Air Liquide's 100-MW electrolyzer, a volume corresponding to the share of H2 delivered to the TotalEnergies Normandy refinery.

Long-term green H2 supply contracts. In June 2024, TotalEnergies and Air Products announced an agreement for the supply of 70,000 tpy of green H2 to the refining and chemicals sites in Europe for a period of 15 yr from 2030. This green H2 will be produced from green ammonia imported by Air Products and will reduce CO2 emissions by up to 700,000 tpy of CO2e.

In Germany, TotalEnergies and VNG, a German natural gas distribution company, signed an agreement in June 2023 to supply green H2 to the TotalEnergies Leuna refinery. The green H2 will be produced using renewable electricity from a 30-MW electrolyzer built and operated by VNG and its partner Uniper. This agreement will contribute to the emissions reduction of the Leuna refinery by reducing GHG emissions by up to 80,000 tpy of CO2e by 2030.

Also in Germany, TotalEnergies signed an agreement with RWE in March 2025 for the long-term supply of 30,000 tpy of green H2 to its Leuna refinery. The green H2 will be produced by a 300-MW electrolyzer built and operated by RWE in Lingen. Delivered via a 600 km pipeline to the Leuna refinery, which must be implemented by the German authorities, it will avoid the emission of around 300,000 tpy of CO2e, from 2030 onwards.