News

AEM electrolyzer to deliver cheaper green H2, to be deployed end 2025 by Horizon

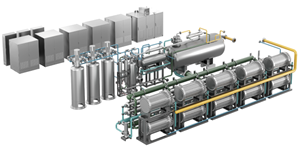

Horizon is redefining the viability of green H2 production, enabling lower cost green H2 for sectors such as steel production, ammonia, methanol and zero emission transportation through its electrolyzer subsidiary HET Hydrogen. The first of the groundbreaking 5-MW systems are currently being prepared for deployment with a subsidiary of Rockcheck Steel Group Co Ltd., a leading industrial enterprise in Tianjin, China.

The collaboration with Rockcheck Steel is part of an integrated system of photovoltaics / H2 / H2-enriched smelting, utilizing a 17-MW building-integrated photovoltaic (BIPV) system and two 5-MW (1,000 Nm³/h) AEM H2 production systems. The green H2 produced will be injected into the gas pipeline for blast furnace operations at Rockcheck Steel Group, aiming to reduce coal consumption and carbon emissions. The world-first electrolyzer is expected to be operational around the end of 2025, accelerating and promoting sustainable H2 in the progressive decarbonization of steel production, one of the most difficult to abate industry sectors.

As an important part of the global energy transition, the interest in H2 as a decarbonization tool is high, but the cost of H2 has been a hurdle to widespread adoption. Horizon's modular AEM system provides a convenient and cost-effective solution for large-scale production of green H2, enhancing the transition to green fertilizers and green chemicals, and the move to more sustainable heavy industry. Horizon's AEM system reduces power consumption by 10%–20% compared to traditional alkaline technology and will demonstrate a lower levelized cost of H2 (LCOH) than alkaline electrolyzer systems. With the AEM equipment deployed on large scale, the capital cost of AEM is also expected to challenge that of alkaline equipment, the key selling point of that traditional technology.

The successful completion of this project will pave the way for the deployment of Horizon AEM systems with renewable power projects around the world, providing more efficient H2 production from photovoltaic, wind and other renewable power sources. It accommodates intermittent power input and improves the utilization of renewable energy to produce green H2 at a cost as low as $2/kg. This delivers highly competitive green H2 solutions for downstream applications such as green ammonia, green alcohols, H2 metallurgy, and transportation.

Green ammonia is the next target for meaningful validation of AEM electrolysis at scale, with increasing interest in ammonia not only as a H2 carrier, but also as a direct fuel for gradual decarbonization of power generation and global shipping operations. To that end, Horizon is currently collaborating with third parties to design a flexible green ammonia production scheme.

Horizon Fuel Cell and electrolyzer subsidiary HET Hydrogen will continue to promote technological innovation in both green H2 production and its applications, with a mandate of improving the viability of the H2 economy.